E-9939

| Order No. |

№ | Number of Poles |

Compatible Chucks |

Weight (kg) |

Drawing | Product BOX |

CAD | Production | Stock Status |

|---|---|---|---|---|---|---|---|---|---|

| 109151 | MSC304HD70 | 12 | MTB304HD70 | 9.4 | View | Add | DATA | Stock Item | Stock△ |

| 109152 | MSC306HD70 | 18 | MTB306HD70 | 13.6 | View | Add | DATA | Stock Item | Stock△ |

| 109153 | MSC308HD70 | 24 | MTB308HD70 | 17.8 | View | Add | DATA | Stock Item | Stock△ |

| 109154 | MSC310HD70 | 30 | MTB310HD70 | 21.5 | View | Add | DATA | Stock Item | Stock△ |

| 109155 | MSC404HD70 | 16 | MTB404HD70 | 12 | View | Add | DATA | Stock Item | Contact |

| 109156 | MSC406HD70 | 24 | MTB406HD70 | 17.2 | View | Add | DATA | Stock Item | Stock△ |

| 109157 | MSC408HD70 | 32 | MTB408HD70 | 22.6 | View | Add | DATA | Stock Item | Stock△ |

| 109158 | MSC410HD70 | 40 | MTB410HD70 | 27.2 | View | Add | DATA | Stock Item | Stock△ |

| 109159 | MSC504HD70 | 20 | MTB504HD70 | 14.3 | View | Add | DATA | Stock Item | Stock△ |

| 109160 | MSC506HD70 | 30 | MTB506HD70 | 20.6 | View | Add | DATA | Stock Item | Stock△ |

| 109161 | MSC508HD70 | 40 | MTB508HD70 | 27.1 | View | Add | DATA | Stock Item | Stock△ |

| 109162 | MSC510HD70 | 50 | MTB510HD70 | 32.7 | View | Add | DATA | Stock Item | Stock△ |

| 109163 | MSC606HD70 | 36 | MTB606HD70 | 25.5 | View | Add | DATA | Stock Item | Stock△ |

| 109164 | MSC608HD70 | 48 | MTB608HD70 | 33.5 | View | Add | DATA | Stock Item | Stock△ |

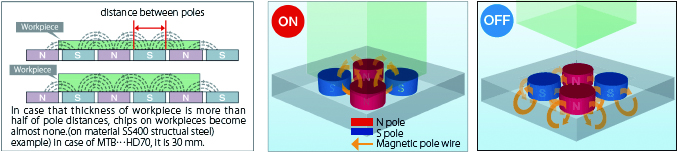

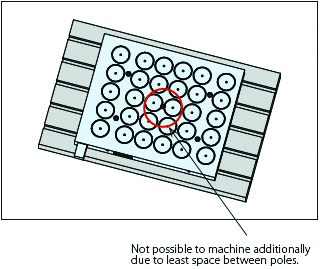

… but least chips on work-surfaces(per pole of dia.70mm under Max conditions)

Cutting thrust on milling is not in the same directions, so need strong adsorption force.

Each magnetic pole contains strong neodymium magnets to generate strong force.

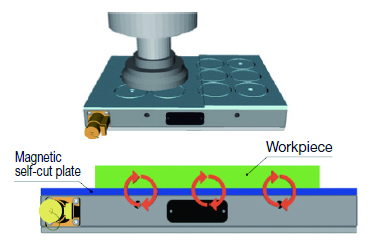

As Magnetism fl ows from N pole to S pole within workpiece, least chips on workpieces.

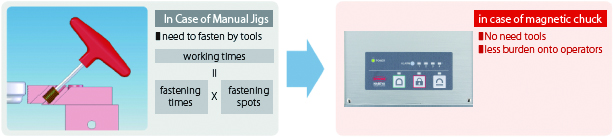

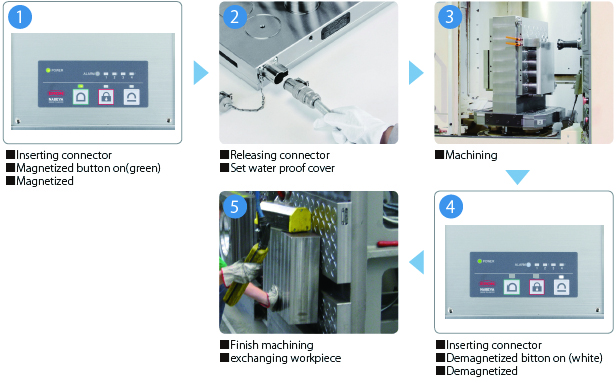

Manual jigs need tool operations, but magnetic chuck only push the buttons

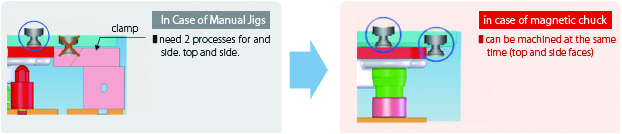

No interference on cutting tools being clamped from the bottom.

Sometimes, Standard Magnetic chucks can not be placed on machine table due to irregular table shape.

Custom made magnetic chuck can be manufactured for such kind of customers.

【e.g.】

Standard MTB506HD70 |

Custom Made MTB506HD70 |

Examples for custom made MTB chucks

①Change the pitch of magnetic poles.

②Change the outside dimensions.

③Delete clamping grooves on both sides.

There can be some restrictions on making custom made chucks.

Adsorption force of magnetic chuck can be changed depending on various kind of conditions.

Before using, please check and concider whether this item can be used well or not for your purpose.

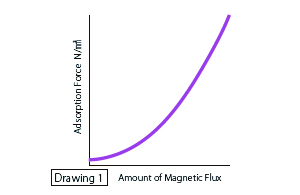

①Conditions concerned adsorption force Magnetic fl ux density

| Amount of magnetic flux being passed through workpiece decide the adsorption force, which means that as much as magnetic fl ux must be taken into workpiece. In case of general clamping, it is important to set properly on N and S pole to get magnetic fl ux as much as possible. (drawing 1) |  |

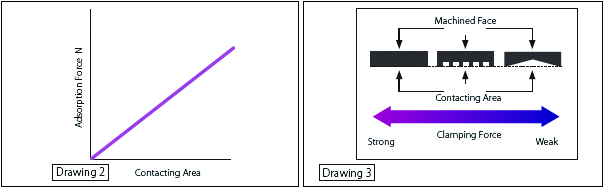

②Conditions regarding adsorption force Contacting area

If contacting areas become double, amount of magnetic fl ux and clamping force also come to be double (drawing 2). and continuous contact surfaces become bigger, then adsorption forces beome higher. (drawing 3)

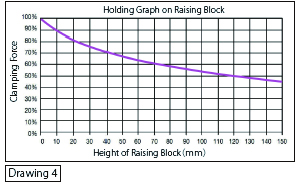

③Conditions regarding adsorption force Height of raising block

| Higher raising block means less amount of magnetic flux through workpiece. Need to check attenuation rate (drawing 4) |

|

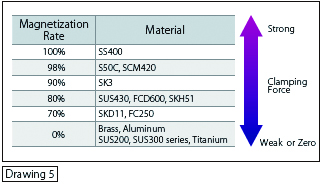

④Conditions regarding adsorption force Material of workpieces

| Materials of workpiece, and jig plates must be checked on its attenuation rate (drawing 5) |  |

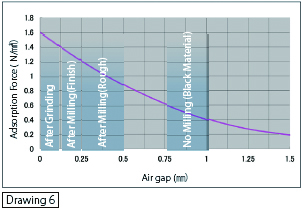

⑤Conditions regarding adsorption force Surface condtions of workpieces

| Adsorption force per unit area can be changed depend on surface conditions of workpiece, and jig plate, which must be checked beofore using. (drawing 6) |  |

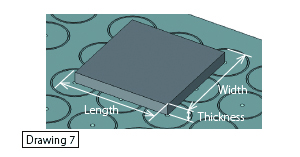

⑥Conditions regarding the adsorption force Recommended workpiece sizes

|

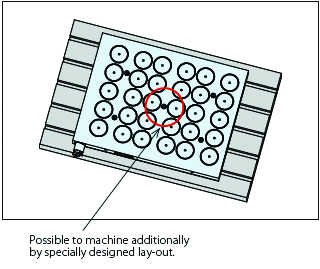

Magnetic fl ux in workpiece fl ows from the center of one pole to other one with. Recommended size of workpiece.

|

|

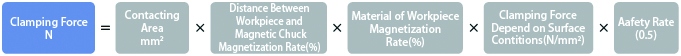

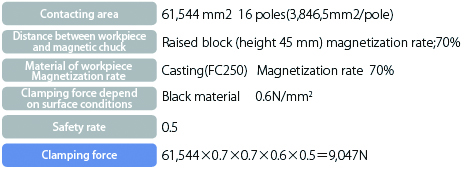

⑦Conditions regarding the adsorption force Calculation of clamping force

【Calculation of adsorption forces】 (Workpiece size: 320 x320 x 35 Casting(FC250))

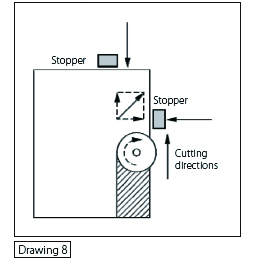

⑧Conditions regarding machining Directions of cutting thrust

| In case that directions of cutting thrust is horizontal to adsorption face, Adsorption force against cutting thrust need approx.. 3-10 times.(coefficient frictions is 0.1-0.3). If not enough holding force, need to set stopper to that directions of cutting thrust(drawing 8) |  |

⑨Conditions regarding remained magnetism Use of demagnetizer

Workpieces after heat treatment can keep remained magnetism Not so easy to release it. Need to remove magnetism by demagnetizer.

Copyright © NABEYA Co.,Ltd. All Rights Reserved.