What are Clamp Units?

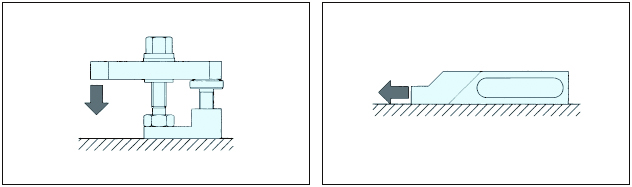

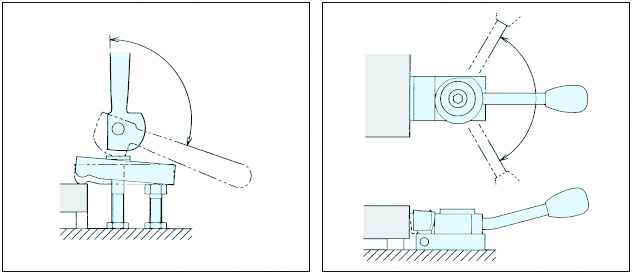

"Clamp units are a class of ""clamping tool"" that consist of multiple parts that can separately attach to the base and clamp workpieces. Clamp units apply a clamping force to the workpiece via a media that uses a mechanism to transmit force from a force generation source (manual, pneumatic, or hydraulic). In these examples, the transmission mechanism is a mechanism such as a screw or cam, and the medium is a clamp bar. Clamp units are categorized into vertical types and horizontal types depending on the direction in which the clamping force is generated."

Selection

Clamp units need to be chosen by taking into account the characteristics of the workpieces (shape, size, accuracy, amount of machining, etc.), the capabilities of the attachment base and machining tools, other jig elements, etc.

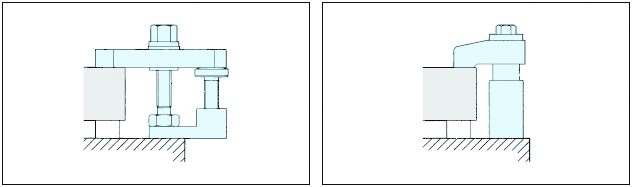

(1) The shapes and sizes of clamp units are affected by interference with other elements and attachment space.

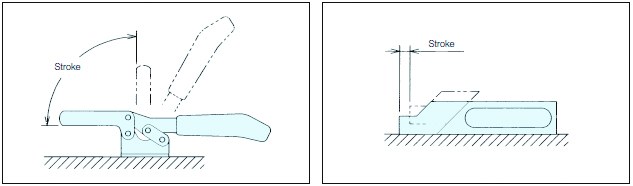

(2) Stroke is the range of motion that occurs when the clamp unit is clamping (or unclamping) a workpiece, and the clamping position needs to be set within the stroke range. The stroke range also has an effect on the ability to desorb the workpiece.

(3) If you require handling of a wide variety of shapes and sizes of workpieces, it is convenient to choose a highly expandable clamp unit.

(4) Operability leads to reduced set-up time and improved work efficiency.

Main Structure

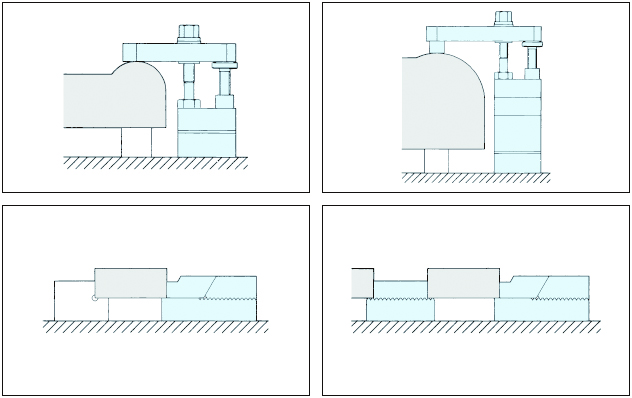

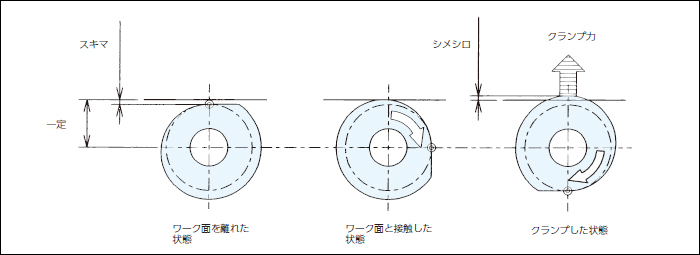

(1) Cum system

The distance from the center of cum to side face of workpiece is same. On the other hand, the distance from side face of cum to its center changes by rotating cum part. This difference which is eccentricity generates clamping force. It's often case that clamping stroke is small. Therefore, the position of clamping unit should be paid attention.

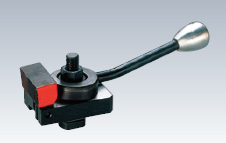

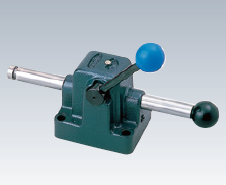

- Clamping unit with cum system

Low Wedge Clamps |

Quick Down Clamps N type |

Quick Down Clamps |

Cum Center Clamp Set |

Swing Clamps |

Quick Locks |

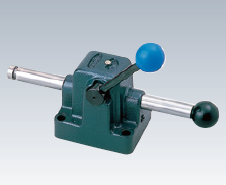

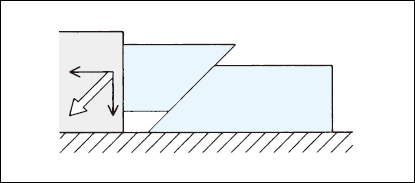

(2) Wedge System

Clamping force is generated by pushing the sliding jaw down between workpiece and the inclined surface of clamping base. As result, workpiece is clamped in vertical and horizontal direction, which prevents workpiece from floating.

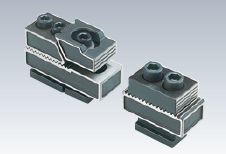

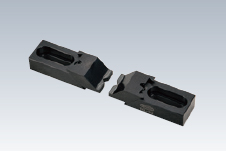

- Clamping units with wedge system

Hold Clamps |

Mini Flat Clamps |

Mini Low Height Clamps |

Toe Adjust Clamps TCL Type |

Toe Adjust Clamps TCH Type |

Aluminium Side Clamps |

(3) Hydraulic System

- Features

-Multiple workpiece can be clamped at the same time. It leads the reduction of setup time.

-Improving of machining accuracy

-Clamping force is almost same value. Therefore, the controlled clamping force which prevent thin shaped workpiece from deforming is possible.

-Clamping at the narrow space is possible with valves.

-Automated manufacturing system is possible by connecting with machining centers and robots.

- Usage

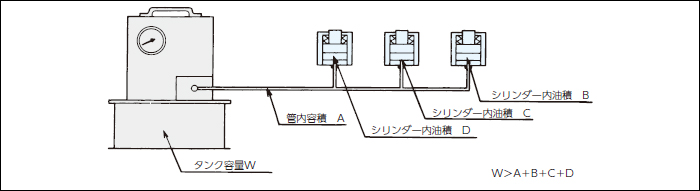

Hydraulic source

-Please use each element within 40MPa accroding to maximum operating pressure.

-The volume of hydraulic oil in oil tank is varied depending on the volume required for cylinder and hydraulic channels.

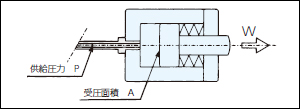

Clamping force

-Clamping force of each element varies depending on the pressure of hydralic resource and the pressure receiving area of piston. Please use our items considering proper clamping force.

W(N)=A(mm2)xP(N/mm2)