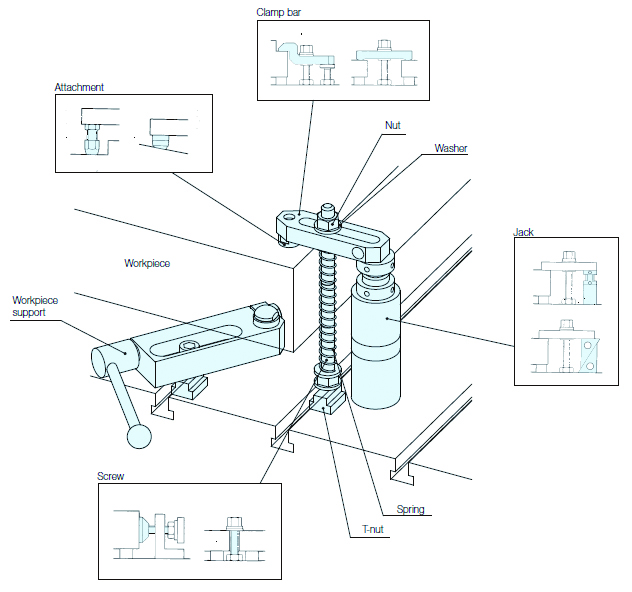

What are Clamping Parts?

Clamping parts are components that make up "clamping tools". Clamping parts can be used for a wide variety of applications, including full tightening and temporally tightening of workpieces in free combinations, and fixing locating parts.

NUT

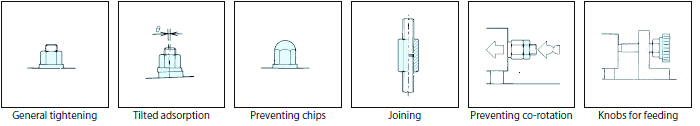

This is used for clamping or feeding the screw part. Select the nut that matches your conditions.

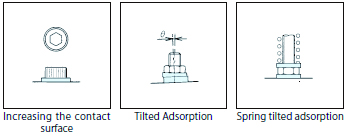

Washers

In addition to protecting the attachment face, these can also be used to prevent tilting such as of springs.

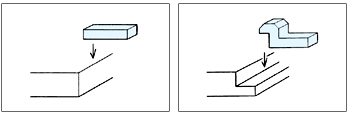

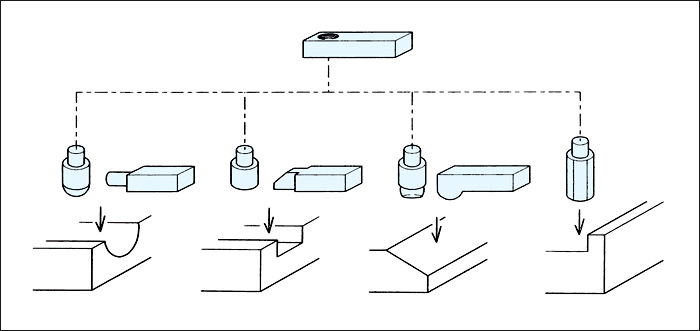

Clamp Bars and Attachments for the Workpiece Surface Shape

There are a wide variety of shapes of parts for clamping workpieces. The range of clamping can be expanded by selecting the clamp bar that matches the shapes or the attachments as needed for the clamp bar.

Attachments are selected based on the surface shape and surface roughness. Attachments made of soft materials or that have been ground can be used for finished surfaces. Attachments with a hard to slide shape need to be chosen for cast surfaces, etc.

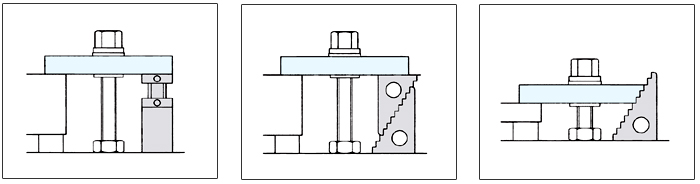

General clamps use adjustable supports that are suitable for the load such as jacks and step blocks.

Furthermore, you can also select clamp bars that have tapped holes for supports or that have an integrated support (leg clamps) to suit your application.

Screw Clamping Force

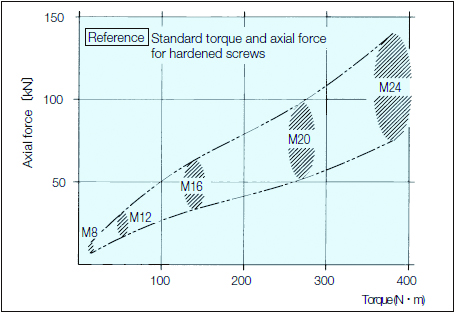

In order to obtain the desired clamping force, it is necessary to know the relationship between the screw torque and axial force. The appropriate clamping can be achieved by using the appropriate torque. If the torque is too low, it can cause the screw to loosen. Similarly, if the torque is too high, there is a risk of deforming or breaking component parts. Care is required because variations in axial force occur due to small differences in friction, surface treatment, hardness, and other factors, even if the screw is the same size. The following table shows a guide that you should check depending on your situation.

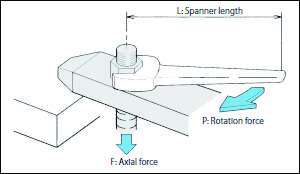

- What is Torque?

Torque is expressed by the product of the length of the spanner with respect to the center of rotation of the screw and the force acting to rotate the spanner, and the axial force of the screw (the force pressing on the clamp bar) is determined by the magnitude of the torque.

Example) What rotation force is required to tighten an M12 (hardened) bolt using a 30 cm (0.3 m) spanner?

Since Torque (T) = P・L, P = T/L

If we assume that the designated torque from the table on the previous page is 50 N・m, we get P = 50/0.3 ≈167 (N).

Furthermore, the axial force that is generated at this time is in the range of 1.5 to 3 tons.

- Screw Clamping Force

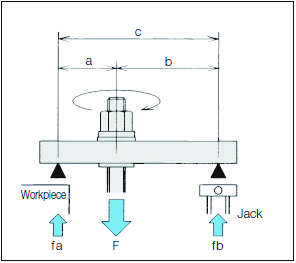

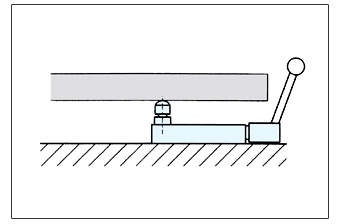

The force applied to both ends of the clamp bar by the axial force that is generated by applying a torque to a screw can be calculated by the following formula.

F = fa+fb ── (1)

fa・a = fb・b ── (2)

F (kN): Axial force of screw fa = F・b/(a+b)

a (cm): Distance between fastening point and clamp end

b (cm): Distance between fastening point and jack end

fa (kN): Force applied to the clamp end

fb (kN): Force applied to the jack

Example) F = 30 kN

a = 5 cm

For b = 10 cm

From Eq. (2)

fb = fa・a/b

Substituting into Eq. (1), the force acting on the clamp end is

fa = F・b/a+b

=30 × 10/15

= 20 (kN)

Furthermore, the force acting on the jack is

fb = F-fa

= 10(kN)

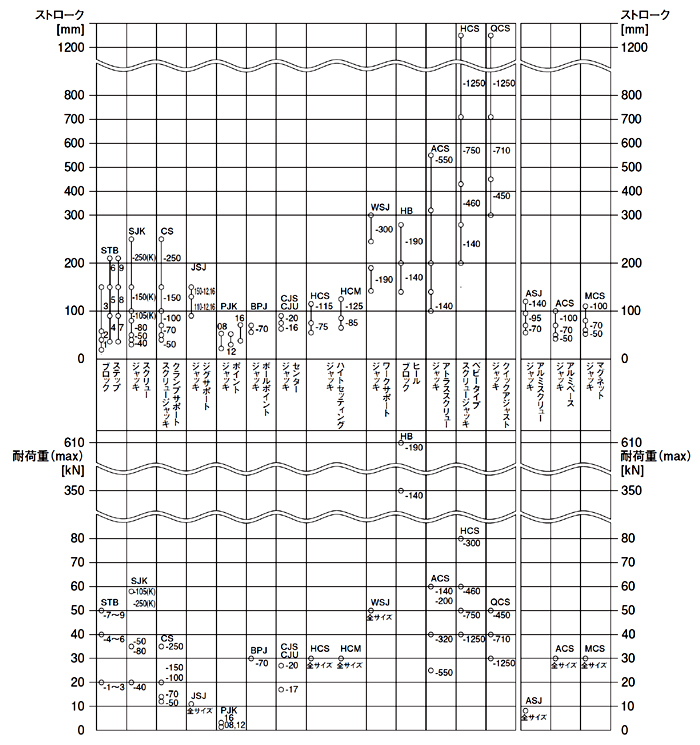

Selection of Jacks

Considering the height of workpiece and loading generated by clamping force, the suitable jacks need to be choosen.

Selection of Screws

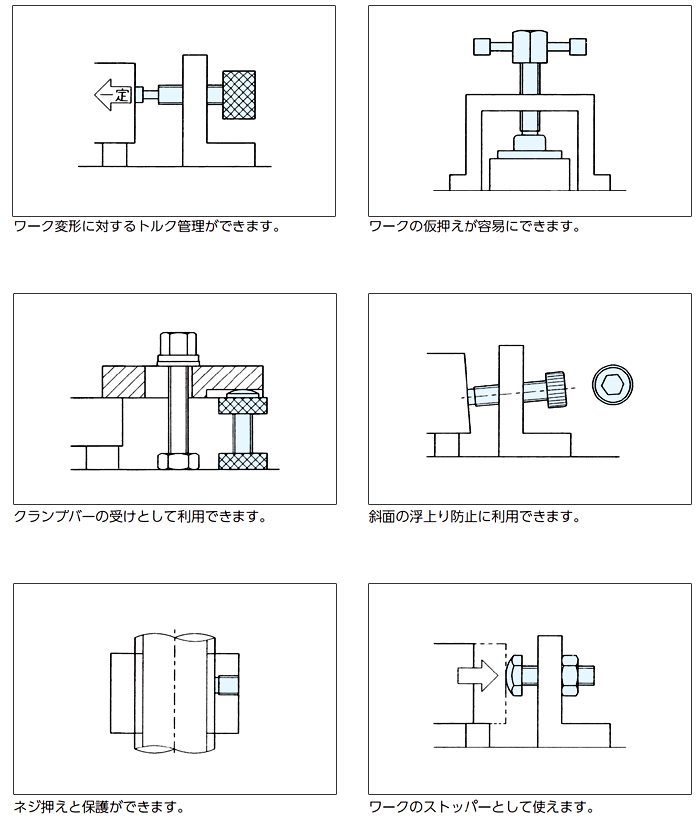

Various application is possible depending on purpose of use 。

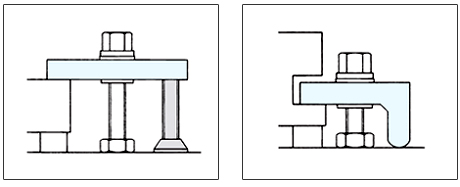

Work Supporting Parts

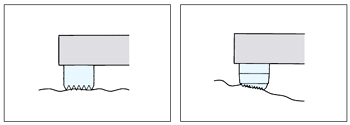

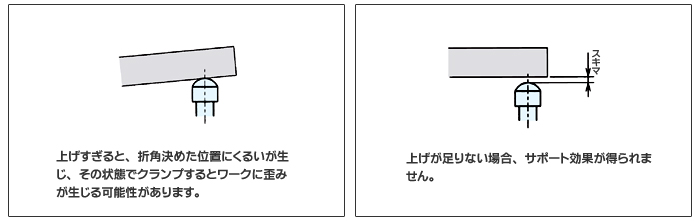

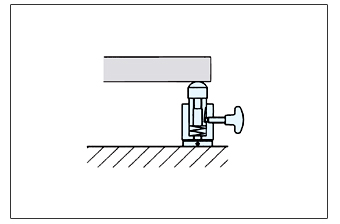

Vibration (Chattering) may occur during machining thin shaped workpiece depending on machining condition. It leads to a product defect or damage of cutting tool. In order to prevent vibration, placing supporting parts with height adjustment function to the vibration source.

Jacks can be used as alternative items, but the deformation of workpiece or decrease in locating accuracy may occur depending on height adjustment.

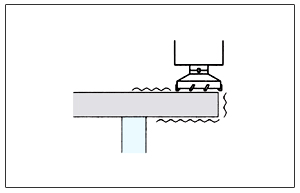

In order to support workpiece stably, there is spring type of supproting part. Stable support is possible by touching workpiece with spring force, and then fixing the height position.

|

|

| Spring is pushed down by workpiece loading. Under the condition, pillow block touches workpiece. And then, stable supporting can be done by fixing it. | It is helpful to use supporting blocks with remoted operation, if supporting at the middle of workpiece is needed. |