Feature

| ●Material FC300 to 250 which are also suitable for jigs are used for attenuation and strength performance as analyzed by FFT vibration analyzer of vibration during machining. |

Complete annealing by natural gas annealing oven |

| ●Heat Treatment Residual stress is released and deformation is prevented by using a natural gas annealing oven that offers complete temperature control for the best thermal efficiency. Aging variations and temperature variations are minimized by complete annealing. |

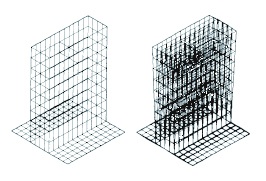

| ●Structure Has a unique structure that keeps deformation and resonance due to load, vibration, and temperature to a minimum through vibration and rigidity analysis using accumulated data and the finite element analysis method (FEM). |

|

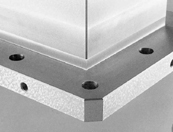

| ●Accuracy The right angle part of the face that touches the edge locator of the horizontal machining center is finished to a high accuracy of within 0.01 by grinding or hand scraping. (MC Tooling Blocks, MC Pallet Sub Tables) |

|

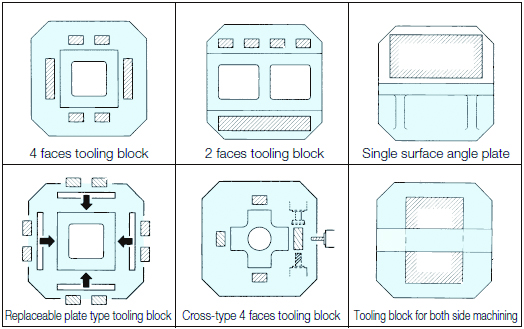

Main Selection Factors for Base Elements

1. Machine specifications

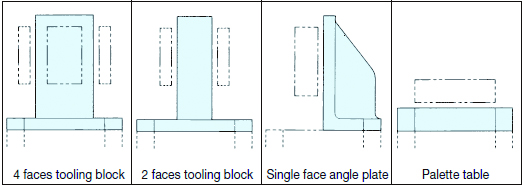

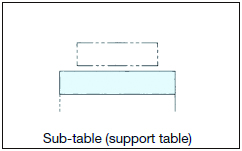

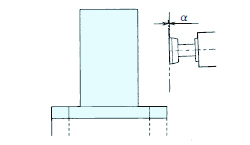

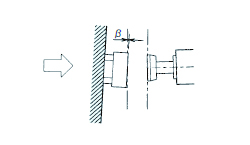

Spindle direction:The type of base element varies depending on the main spindle direction.

Horizontal type |

|

Vertical type |

|

| Table size: ・You generally select the base element that is the same size as the machine table. ・For horizontal machining centers, the table specifications are set by the JIS standard. The base elements are designed with mounting holes and locating based on this JIS standard. ・For vertical machines, consideration needs to be given to attachment method, oil channels, etc. |

|

|

|

|

|

| Set the mounting holes to match the machine table. | If you are using an attachment clamp, space is needed for clamping. | Selection of a size that takes the oil channel into account is required. | Another method is to create overhang to account for interference, load weight, and other factors. This is an enlargement of the working area. |

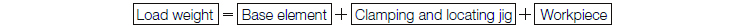

Load weight:Base elements and jigs need to be installed on the machine table within the load weight limit.

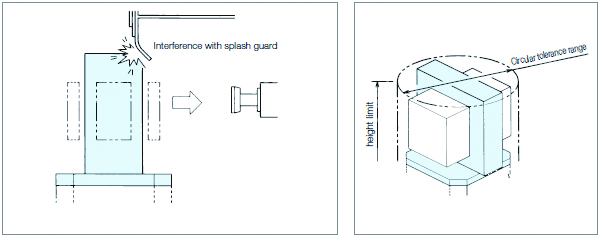

Other: In horizontal machining centers, in particular, interference with the splash guard may occur depending on the height of the base elements.

Furthermore, the interference area such as due to rotation is also defined.

Selection needs to take into account the combination of base elements, workpieces, and jigs.

2. Production methods and workpieces

Selection of the base element varies depending on the following conditions.

(Horizontal machining center in particular)

| ・Workpiece size ・Workpiece type ・Number of processes ・Number of products and other factors |

|

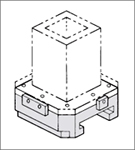

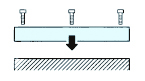

Self-cutting

Virtually all multi-face tooling blocks have self-cut allowance dimension.

Self-cut offers a finish with accuracy that matches the machine you are using.

|

|

|

| For every machine, the error is not strictly zero. The machine you are using similarly has an error within some permitted range. | If the error in the machine you are using, the error in the base element, and the error in the locating or other jig fixture, a large error may occur. | By cutting by yourself, you can obtain precision that matches the device. |