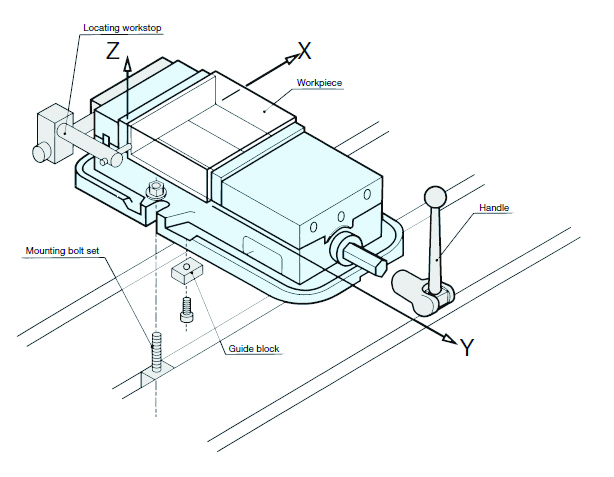

A machine vise is a highly general-purpose jig that combines:

①A locating function for the X, Y, and Z axes of the workpiece

②A clamping (mechanical type, hydraulic type) function

③A function for attaching to and locating the machine table

●When used with a vertical machining center or milling machine, the reference for the workpiece is

X-axis direction: A locating element such as a locating workstop

Y-axis direction: Jaw plate face on the stationary jaw side of the vise

Z-axis direction: Sliding surface of the vise

●In a precision vise, the precision of the parallelism of the following is high:

jaw plate surface of stationary jaw side from the machine T-slot in the X-axis direction sliding surface from the machine table surface in the Z-axis direction

Selecting Machine Vises

1.Workpiece size

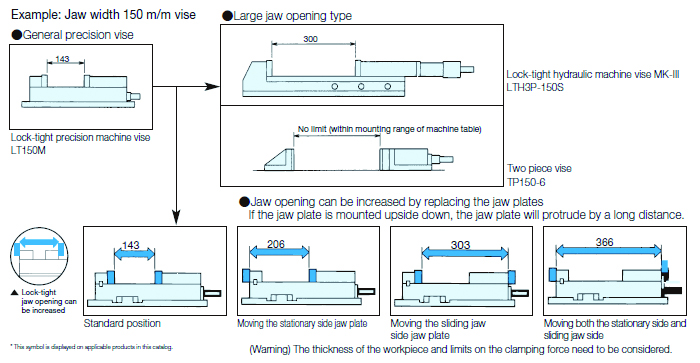

(1)Selection by "jaw opening":

You need to select a vise that has a jaw opening that is able to clamp the workpiece. In general precision vises, the jaw opening is similar to the jaw width. However, for some models, a "type with large jaw openings" or "type where the jaw opening can be increased" by replacing the jaw plates are also available.

(2)Selection by "jaw width":

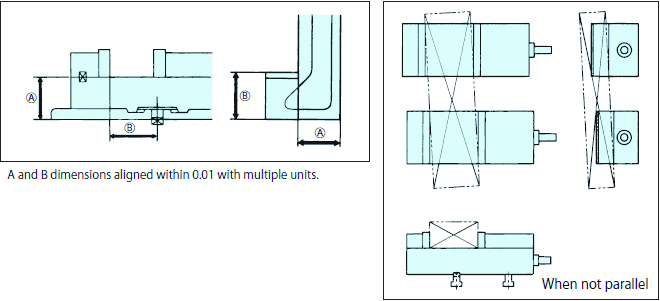

In workpieces that greatly exceed the jaw width (long workpieces, etc.), vibrations (chattering) may occur in the workpiece during machining or the workpiece may fall out. You need to select a vise with a jaw width suitable for the workpiece. For long workpieces, it is useful to arrange several multi-jaw specification products in parallel with the height to the vise sliding surface (A) and the distance between guide block and jaw plate surface (B) within 0.01.

●Multi-jaw specifications