Installation locations and quantity of the leveling blocks

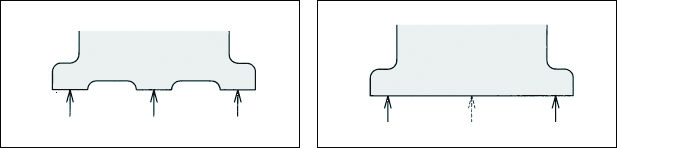

When level points (seating surfaces) are specified on the object which should be adjusted, place the leveling blocks according to the location and quantity of the seating surfaces.

When seating surfaces are not specified, place the leveling blocks where the object is placed most stably. Under normal conditions, place the leveling blocks on each end surface and as necessary, place an additional leveling block in between.

However, installation locations and quantity must be decided by considering conditions of the object such as the shape, rigidity and load.

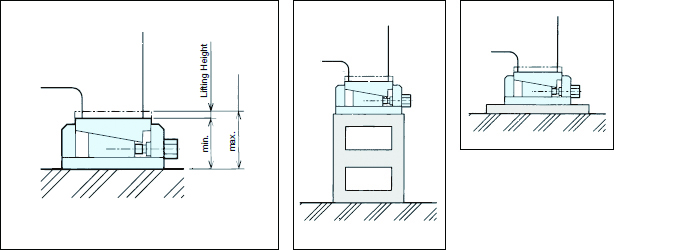

Stroke

The main feature of the leveling block is level adjustment. The lifting height is approximately several millimeters which is the range in which the level adjustments are typically performed.

To adjust the height of the object, a spacer that enables the leveling block to be stably placed while enduring the load is necessary.

Additionally, when the installation surface (such as a floor) is unstable or tilted more than the lifting height, use a liner (flat steel plate).

Maximum allowable load

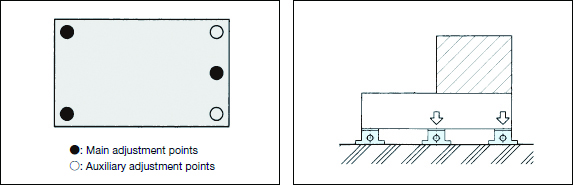

Level adjustment should be performed for 3 points. After adjustment, specify the auxiliary points while taking into consideration the conditions of the object such as rigidity and load. This is important because, in most cases, load is mainly transferred to the desired 3 points.

It is uncommon that the load is always transferred equally to each point. The load on each point may differ depending on the level points, adjustment accuracy, structure of the object and load conditions (such as offset load). When choosing leveling blocks based on the load conditions, use the following formula.

Leveling Block Maximum allowable load of a single leveling block > (Weight of the object + Load weight)÷3

It is recommended that you use the same model for all points.

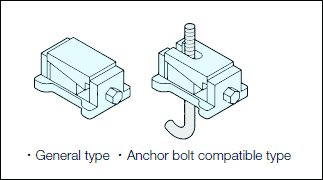

Using an anchor bolt

An anchor bolt may not be used for all types of leveling blocks. An anchor bolt can be used for a leveling block with a notch or a through hole by letting the anchor bolt pass through the notch or through hole.

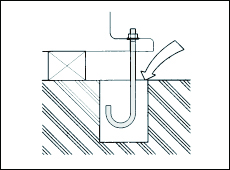

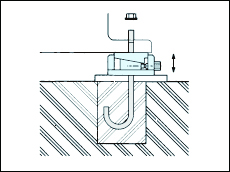

Using an anchor bolt

|

|

| Place the object on a temporary block for which the heights of the leveling block,etc., are considered. Suspend the anchor bolt and then fix the anchor bolt using mortar, epoxy grout or the like. |

After fixing the anchor bolt, install the leveling block and perform the level adjustment. After the adjustment, tighten the anchor bolt. |

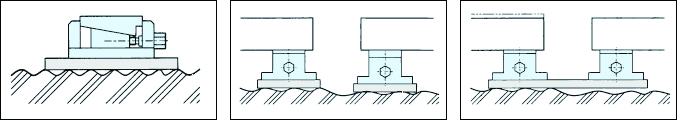

Installation

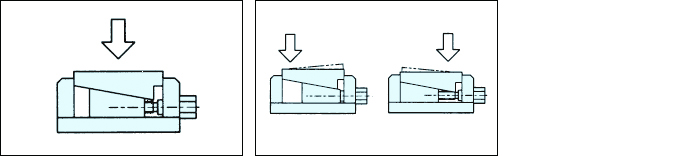

When the floor surface is significantly unstable or tilted, a liner (flat steel plate) must be placed under the leveling block.

Even when placing multiple plates side by side such as surface plates, each set of liner and leveling block must be independent.

Otherwise, the level adjustment for the next leveling block may be affected because of the floor instability or tilting.

When installing the object on the leveling block, be sure to align the loading point to the center of the leveling block.

If the seating surface (point) of the object is narrow and the object is not well-balanced when installed, the load resistance capacity may decrease.

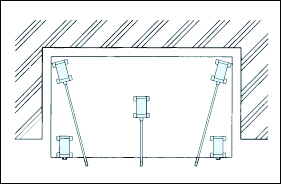

When the object is huge and the level point is located at the center, or when operations cannot be performed easily since the installation location is close to a wall, models equipped with a remote operation handle are useful.