E-9472

| Order No. |

No. | Matching Screw Diameter (Coarse Thread) | Weight(kg) | Drawing | Product BOX |

Production | Stock Status |

CAD |

|---|---|---|---|---|---|---|---|---|

| 935723 | PCS0006 | M 6-M8 | 1.7 | View | Add | Stock Item | Stock〇 | |

| 929997 | PCS0008 | M 8-M8 | 1.7 | View | Add | Stock Item | Stock〇 | DATA |

| 936630 | PCS0010 | M10-M8 | 1.7 | View | Add | Stock Item | Stock〇 | |

| 936631 | PCS0012 | M12-M8 | 1.8 | View | Add | Stock Item | Stock〇 |

|

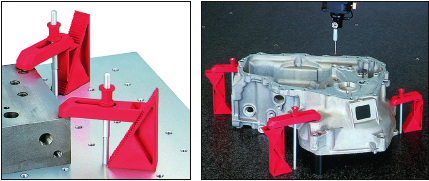

Step Blocks 28.8H, 45.3H, 94.8H 4 pieces of each (Engineering plastic) |

|

Stud Bolts M8 × 100, 125, 150, 175, 200 4 pieces of each (Aluminum A5056 with alumite surface treatment) |

|

Step Clamps 63.5L, 101.6L, 152.4L 2 pieces of each (Engineering plastic) |

|

Double Flanged Nuts 10 pieces of M8 (Engineering plastic) |

|

Plain clamp 63.5L, 101.6L, 152.4L 2 pieces of each (Engineering plastic) |

1993 Designated as Ministry of International Trade and Industry Good Design Product |

|

| Property | Specific Gravity |

Water Absorption Ratio |

Heat Distortion Temperature |

Thermal Conductivity |

Linear Expansion Coefficient |

Fire Resistance |

| Units | - | % | ℃ | cal/(cm・s・℃) | 1℃ | UL 94 standard |

| Conditions | 23℃ | 20°C for 30 days | 18.6kg/cm | - | -30℃~+30℃ | 1.6mmBar |

| Data | 1.41 | 0.35 | 208 | 4.0x10-4 | 3~8x10-5 | HB |

| Property | Tensile Strength Yield Point |

Tensile Rupture Point |

Bending Strength |

Bending Elasticity |

Izod Impact Strength |

Insulation Breakdown Strength |

Arc Resistance |

| Units | N/mm2 | % | N/mm2 | N/mm2 | kJ/m2 | kv/m | sec |

| Conditions | 23℃ | 23℃ | 23℃ | 23℃ | 1/8″ × 1/2″ 23°C bar with notch |

D149 | D495 |

| Data | 97 | 4~6 | 170 | 5200 | 650 | Short time method 20 Step method 15 |

125 |

Copyright © NABEYA Co.,Ltd. All Rights Reserved.