E-9990

| Order No. |

№ | Jaw Width |

Jaw Depth |

Maximum Jaw Opening |

Standard Guide Block Width |

Clamping Force (kN) |

Weight (kg) |

Drawing | Product BOX |

CAD | Production | Stock Status |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 970115 | LTCV100 | 102 | 45 | 145 | 18 | 30 | 20.5 | View | Add | DATA | Stock Item | Stock△ |

| 970116 | LTCV125 | 125 | 50 | 210 | 18 | 30 | 30 | View | Add | DATA | Stock Item | Stock〇 |

| 970117 | LTCV160 | 160 | 60 | 300 | 18 | 30 | 50 | View | Add | DATA | Stock Item | Stock△ |

| 980869 | LTCV200 | 200 | 70 | 410 | 18 | 30 | 69 | View | Add | DATA | Stock Item | Stock△ |

| 970118 | LTCV100H | 102 | 45 | 145 | 18 | 30 | 21 | View | Add | DATA | Stock Item | Stock〇 |

| 970119 | LTCV125H | 125 | 50 | 210 | 18 | 30 | 30 | View | Add | DATA | Stock Item | Stock〇 |

| 970120 | LTCV160H | 160 | 60 | 300 | 18 | 30 | 50 | View | Add | DATA | Stock Item | Stock〇 |

| 980870 | LTCV200H | 200 | 70 | 410 | 18 | 30 | 69 | View | Add | DATA | Stock Item | Stock〇 |

| 986025 | LTCV100S | 102 | 45 | 145 | 18 | 30 | 20.5 | View | Add | DATA | × | Stock△ |

| 986026 | LTCV125S | 125 | 50 | 210 | 18 | 30 | 30 | View | Add | DATA | × | Stock△ |

| 986027 | LTCV160S | 160 | 60 | 300 | 18 | 30 | 50 | View | Add | DATA | × | Contact |

| 986028 | LTCV200S | 200 | 70 | 410 | 18 | 30 | 69 | View | Add | DATA | × | Stock△ |

| 986029 | LTCV100SH | 102 | 45 | 145 | 18 | 30 | 21 | View | Add | DATA | × | Stock△ |

| 986030 | LTCV125SH | 125 | 50 | 210 | 18 | 30 | 30 | View | Add | DATA | × | Stock△ |

| 986031 | LTCV160SH | 160 | 60 | 300 | 18 | 30 | 50 | View | Add | DATA | × | Stock△ |

| 986032 | LTCV200SH | 200 | 70 | 410 | 18 | 30 | 69 | View | Add | DATA | × | Stock△ |

| 986033 | LTCV160TH | 160 | 60 | 300 | 18 | 30 | 50 | View | Add | DATA | Stock Item | Contact |

| 986034 | LTCV200TH | 200 | 70 | 410 | 18 | 30 | 70 | View | Add | DATA | Stock Item | Stock△ |

| 147434 | LTCV100-14GB | 102 | 45 | 145 | 14 | 30 | 20.5 | View | Add | DATA | × | Stock△ |

| 147435 | LTCV125-14GB | 125 | 50 | 210 | 14 | 30 | 30 | View | Add | DATA | × | Contact |

| 147436 | LTCV100H-14GB | 102 | 45 | 145 | 14 | 30 | 20.5 | View | Add | DATA | × | Stock△ |

| 147437 | LTCV125H-14GB | 125 | 50 | 210 | 14 | 30 | 30 | View | Add | DATA | × | Stock△ |

| 147438 | LTCV100S-14GB | 102 | 45 | 145 | 14 | 30 | 20.5 | View | Add | DATA | × | Contact |

| 147439 | LTCV125S-14GB | 125 | 50 | 210 | 14 | 30 | 30 | View | Add | DATA | × | Stock△ |

| 147440 | LTCV100SH-14GB | 102 | 45 | 145 | 14 | 30 | 20.5 | View | Add | DATA | × | Contact |

| 147441 | LTCV125SH-14GB | 125 | 50 | 210 | 14 | 30 | 30 | View | Add | DATA | × | Contact |

Air blow mechanism |

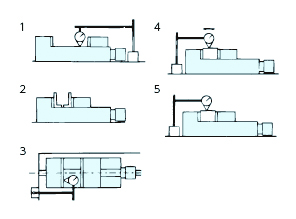

On the mechanical type, the handle can also be operated from the stationary jaw side. |

| No. | Inspection Points (per 100 mm) | Former JIS Standard (O Grade) |

Nabeya Standard Value |

|

| 1 | Parallelism between bottom surface of main body and sliding surface | 0.015 | 0.010 | |

| 2 | Perpendicularity between jaw plate and sliding surface | 0.030 | 0.015 | |

| 3 | Perpendicularity between T-slot and jaw plate surface of stationary jaw side. | 0.015 | 0.015 | |

| 4 | Parallelism between top surface of clamped test block and bottom surface of main body | 0.020 | 0.015 | |

| 5 | Lift-up of top surface of clamped test block | 0.030 | 0.015 |

|

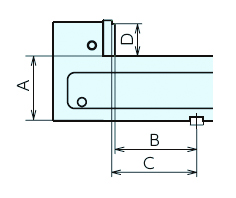

*For the SJ type, the parallel standards for matched specification products are as follows. A: 0.01 or less B, C, D: 0.02 or less |

|

As long as they are the same size, all products are parallel no matter how many pieces. There is no charge for parallel products. ◆When purchasing for the first time ◆For additional orders |

|

E-9275B/MACHINE VISE SERIES ACCESSORIES

E-9275B/MACHINE VISE SERIES ACCESSORIES E-9275B/MACHINE VISE SERIES ACCESSORIES

E-9275B/MACHINE VISE SERIES ACCESSORIES E-9275B/

E-9275B/ E-9275B/MACHINE VISE SERIES ACCESSORIES

E-9275B/MACHINE VISE SERIES ACCESSORIES E-9275B/

E-9275B/Copyright © NABEYA Co.,Ltd. All Rights Reserved.