E-1101

| Order No. |

№ | Size | Weight (kg) | Drawing | Product BOX |

CAD | Production | Stock Status |

|---|---|---|---|---|---|---|---|---|

| 109778 | VCM0303E | 300x300x40 | 8.5 | View | Add | DATA | Stock Item | Stock〇 |

| 109779 | VCM0303S | 300x329x40 | 9 | View | Add | DATA | Stock Item | Stock△ |

| 170071 | VCM0405E | 500x400x40 | 18 | View | Add | DATA | × | Contact |

| 170072 | VCM0405E-2 | 500x800x40 | 36.1 | View | Add | DATA | × | Contact |

| Order No. |

№ | Stopper Block | CompatiBle Models | Weight (kg) | Drawing | Product BOX |

CAD | Production | Stock Status |

|---|---|---|---|---|---|---|---|---|---|

| 114333 | VCM-SB1 | A | All Sizes | 0.069 | View | Add | DATA | Stock Item | Stock〇 |

| 114334 | VCM-SB2 | B | All Sizes | 0.09 | View | Add | DATA | Stock Item | Stock〇 |

| Order No. |

№ | Size | Drawing | Product BOX |

Production | Stock Status |

|---|---|---|---|---|---|---|

| 116968 | VCM-G1.5 | φ4ⅹ1.5m | View | Add | × | Stock△ |

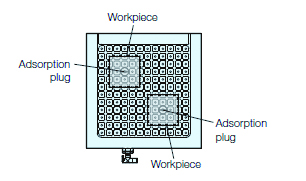

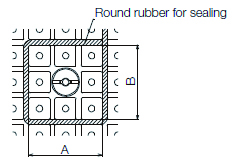

(1) The adsorption surface is created by attaching an adsorption plug, plug, round for sealing, and locating pin according to the shape of workpiece.

|

The area enclosed by the round rubber for sealing forms the adsorption area. The adsorption area has a large eff ect on the adsorption force. However, if the round rubber for sealing is on the outside of the workpiece, there is virtually no adsorption. The area should be enclosed by as large a round rubber for sealing as possible that will fi t inside the workpiece. |

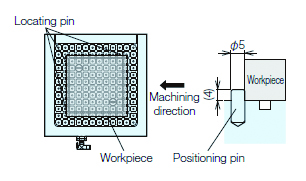

(2) Place the locating pin in the hole in the used surface of the vacuum chuck.

|

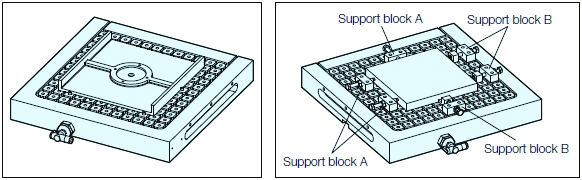

The locating pin is not only for locating the workpiece, but can also be used as a stopper against cutting resistance in the horizontal direction during cutting. Stopper block A and stopper block B, which are sold separately, can also be mounted on holes in the used surface. |

(3) Mount the workpiece, connect the air, and turn the supply valve on to activate the adsorption.

The workpiece can be removed by turning the supply valve off .

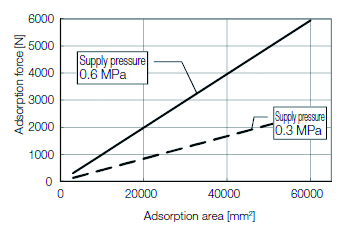

Note that these should be used as reference values since the adsorption force varies depending on the condition of the workpiece and how the round rubber for sealing is arranged.

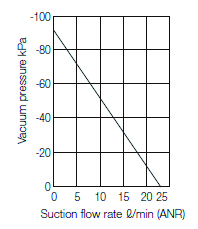

If a vacuum pressure gauge is fi tted to the VCM0303S, the adsorption force can also be calculated accurately using the following formula.

Adsorption force (N) = Vacuum pressure (kPa)× adsorption area (mm2)× 0.001

|

Vacuum pressure (kPa): Value on vacuum pressure gauge |

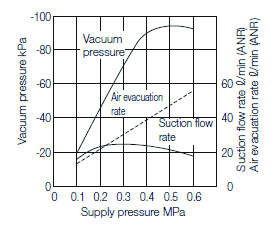

The flow rate characteristics show the characteristics when the supply pressure is 0.45 MPa.

Exhaust characteristics |

Flow rate characteristics |

The speed controller is shipped already adjusted. You should not adjust it yourself. Doing so could cause the vacuum pressure gauge to break.

In order to generate stable adsorption force, a pressure of 0.3 to 0.6 MPa needs to be supplied continuously. The seal rubber should be arranged so that it is inside the workpiece. If the seal rubber is outside the workpiece, it can cause the adsorption force to decrease.

Copyright © NABEYA Co.,Ltd. All Rights Reserved.