E-9775Q

| Type | Order No. | No. | Jaw Width |

Jaw Depth |

Jaw Opening |

Standard Guide Block Width |

Clamping Force kN |

Weight (kg) |

Drawing | Product BOX |

CAD | Production | Stock Status |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Q | 962282 | LTFV100Q | 102 | 45 | 140 | 18 | 25 | 25.5 | View | Add | DATA | Stock Item | Stock△ |

| Q | 952058 | LTFV125Q | 125 | 50 | 200 | 18 | 30 | 35 | View | Add | DATA | Stock Item | Stock〇 |

| Q | 952059 | LTFV150Q | 150 | 60 | 260 | 18 | 40 | 58 | View | Add | DATA | Stock Item | Stock△ |

| Q | 952060 | LTFV175Q | 175 | 70 | 280 | 18 | 40 | 79 | View | Add | DATA | Stock Item | Stock△ |

| QG(Matched Specification) | 962283 | LTFV100QG | 102 | 45 | 140 | 18 | 25 | 25.5 | View | Add | DATA | Stock Item | Stock△ |

| QG(Matched Specification) | 952064 | LTFV125QG | 125 | 50 | 200 | 18 | 30 | 35 | View | Add | DATA | Stock Item | Stock〇 |

| QG(Matched Specification) | 952065 | LTFV150QG | 150 | 60 | 260 | 18 | 40 | 58 | View | Add | DATA | Stock Item | Stock△ |

| QG(Matched Specification) | 952066 | LTFV175QG | 175 | 70 | 280 | 18 | 40 | 79 | View | Add | DATA | Stock Item | Stock△ |

| Type | Order No. | No. | Jaw Width |

Jaw Depth |

Jaw Opening |

Standard Guide Block Width |

Clamping Force kN |

Weight (kg) |

Drawing | Product BOX |

CAD | Production | Stock Status |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Q | 952061 | LTFH125Q | 125 | 50 | 200 | 18 | 30 | 35 | View | Add | DATA | Stock Item | Stock△ |

| Q | 952062 | LTFH150Q | 150 | 60 | 260 | 18 | 40 | 58 | View | Add | DATA | Stock Item | Stock△ |

| Q | 952063 | LTFH175Q | 175 | 70 | 280 | 18 | 40 | 79 | View | Add | DATA | Stock Item | Stock△ |

| QG(Matched Specification) | 952067 | LTFH125QG | 125 | 50 | 200 | 18 | 30 | 35 | View | Add | DATA | Stock Item | Stock△ |

| QG(Matched Specification) | 952068 | LTFH150QG | 150 | 60 | 260 | 18 | 40 | 58 | View | Add | DATA | Stock Item | Stock△ |

| QG(Matched Specification) | 952069 | LTFH175QG | 175 | 70 | 280 | 18 | 40 | 79 | View | Add | DATA | Stock Item | Stock△ |

| Order No. | № | Drawing | Product BOX |

CAD | Production | Stock Status |

|---|---|---|---|---|---|---|

| 962533 | LTQ-80HJ | View | Add | DATA | Stock Item | Contact |

| 962534 | LTQ-200HJ | View | Add | DATA | Stock Item | Stock△ |

*The shape around the handle insertion point differs in the LTFV-100Q.

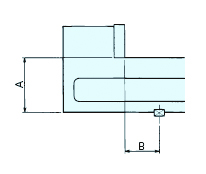

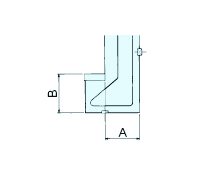

(A and B align within 0.01 no matter how many pieces)

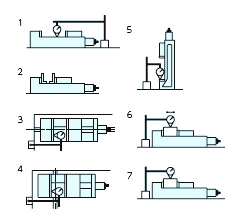

If the suffix of the manufacture no. (attached to the outer box and main body) is the same letter, then the products are parallel no matter how many pieces (for standard guide blocks). There is no charge for parallel products.

◆When purchasing for the first time

Order matched specification products (suffix G).

When ordering, specify the groove width of the machine you are using.

◆For additional orders

Contact us with the suffix letter of the manufacture no. of a vise that you have (stamped on the name plate).

LTFV type |

LTFH Type |

Contact us with the guide block width.

|

|

E-9275B/MACHINE VISE SERIES ACCESSORIES

E-9275B/MACHINE VISE SERIES ACCESSORIES E-9275B/MACHINE VISE SERIES ACCESSORIES

E-9275B/MACHINE VISE SERIES ACCESSORIES E-9275B/MACHINE VISE SERIES ACCESSORIES

E-9275B/MACHINE VISE SERIES ACCESSORIES E-9275B/

E-9275B/Copyright © NABEYA Co.,Ltd. All Rights Reserved.